Laser cutting is good for making flat sheets, but not enough to produce 3D shapes. CNC (Computer Numerical Control) milling is the way to make those. As with laser cutting, you can order CNC services at a reasonable price nowadays. It was even easier for our team – Tartu University’s Institute of Technology has a mill available and Taavi knew how to use it.

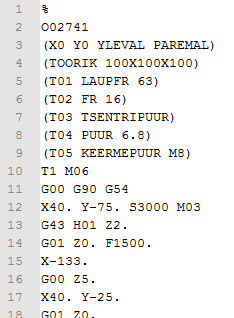

The CNC machine is programmed using a special programming language – the G-code, where each instruction corresponds to some movement of the mill. Ironically, despite the obvious practical importance of this language, most programmers or computer scientists have probably never even heard of it. If you are one of them, take a minute to educate yourself and skim through the Wikipedia entry, at least.

Although the CNC code can in principle be generated by CAM systems straight from the 3D CAD-model, it was easier for us to write the program manually, as it allows to account for the specifics of the particular machine in our case.

In the video below, Taavi is running the code he wrote for cutting the coilgun box for the Telliskivi robot:

And if you think this is cool, you might want to take a look at what the expensive industrial CNC mills can do in the hands of expert programmers: (one), (two).